2020-10-13

Sometimes it has to be something more

RINGSPANN also produces shaft-hub-connections with increased corrosion protection

RINGSPANN offers stainless steel and nickel-coated shaft-hub-connections especially for use in drive trains with increased corrosion protection requirements. Typical applications include gears and pumps in machines and plants in the food processing, pharmaceutical, chemical, packaging and bottling industries. Find out which shrink discs and clamping elements from the company’s portfolio are the first choice here - and what customisation options RINGSPANN offers in terms of corrosion protection.

Bad Homburg, October 2020. – RINGSPANN has in its recent past integrated many more shaft-hub-connections into its one-stop offer for drive technology and has raised the performance level of several series on the basis of an improved frictional connection calculation method. In addition, various external and internal clamping solutions that meet particularly high corrosion protection requirements have now found their way into the portfolio. These include in particular the stainless steel series RLK 603 K (shrink discs) and the nickel-plated series RLK 110 K (cone clamping elements). The main users of these corrosion-resistant shaft-hub-connections from RINGSPANN include, in particular, machine and plant manufacturers in food technology, pharmaceutical and medical technology, chemical and process technology as well as packaging, filling and fluid technology. "Furthermore, manufacturers of agricultural and construction machinery also use these extremely durable components to create weatherproof and wear-resistant drive trains," says Marvin Raquet, product manager for RINGSPANN´s shaft-hub-connections.

High quality stainless steels

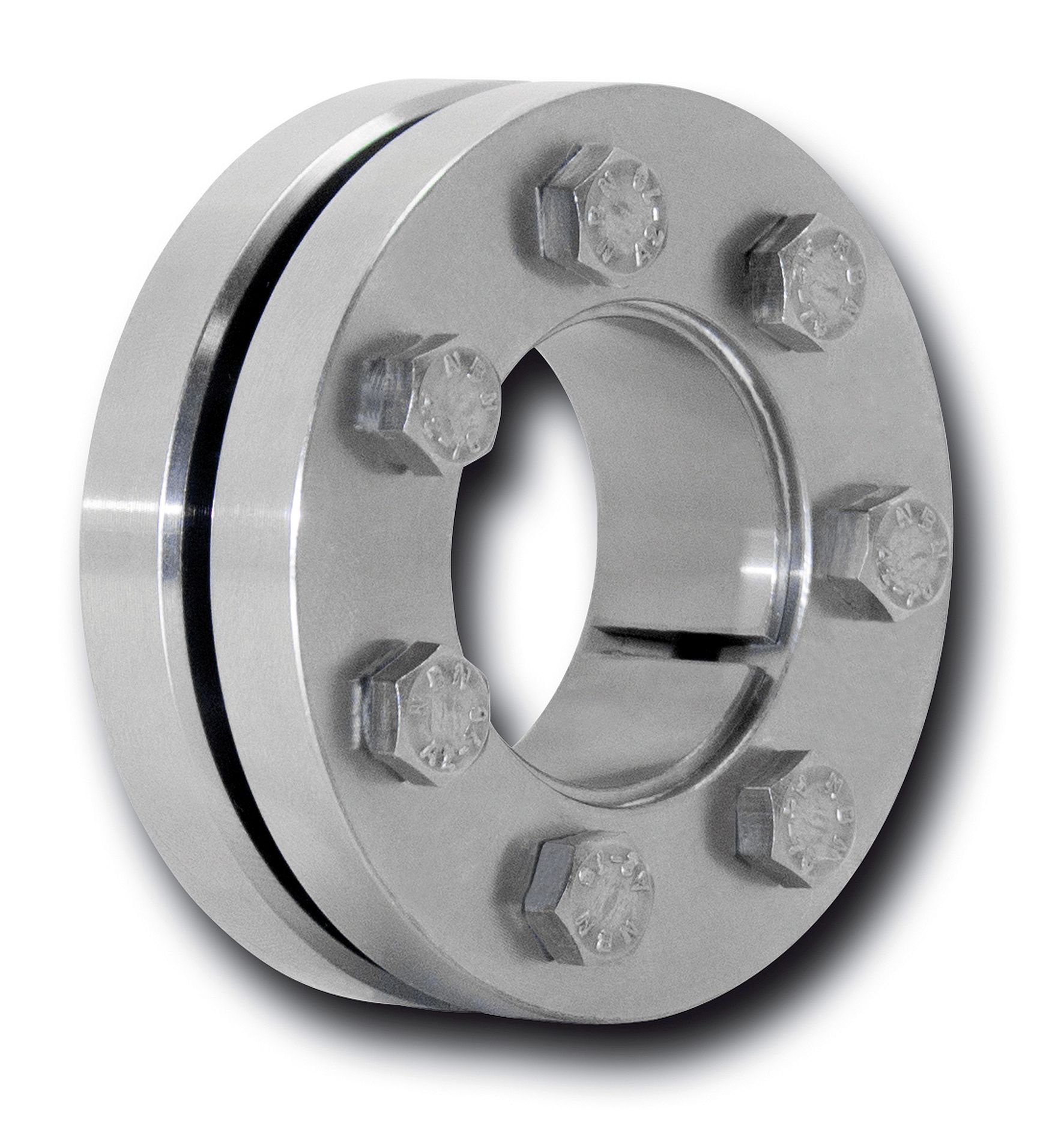

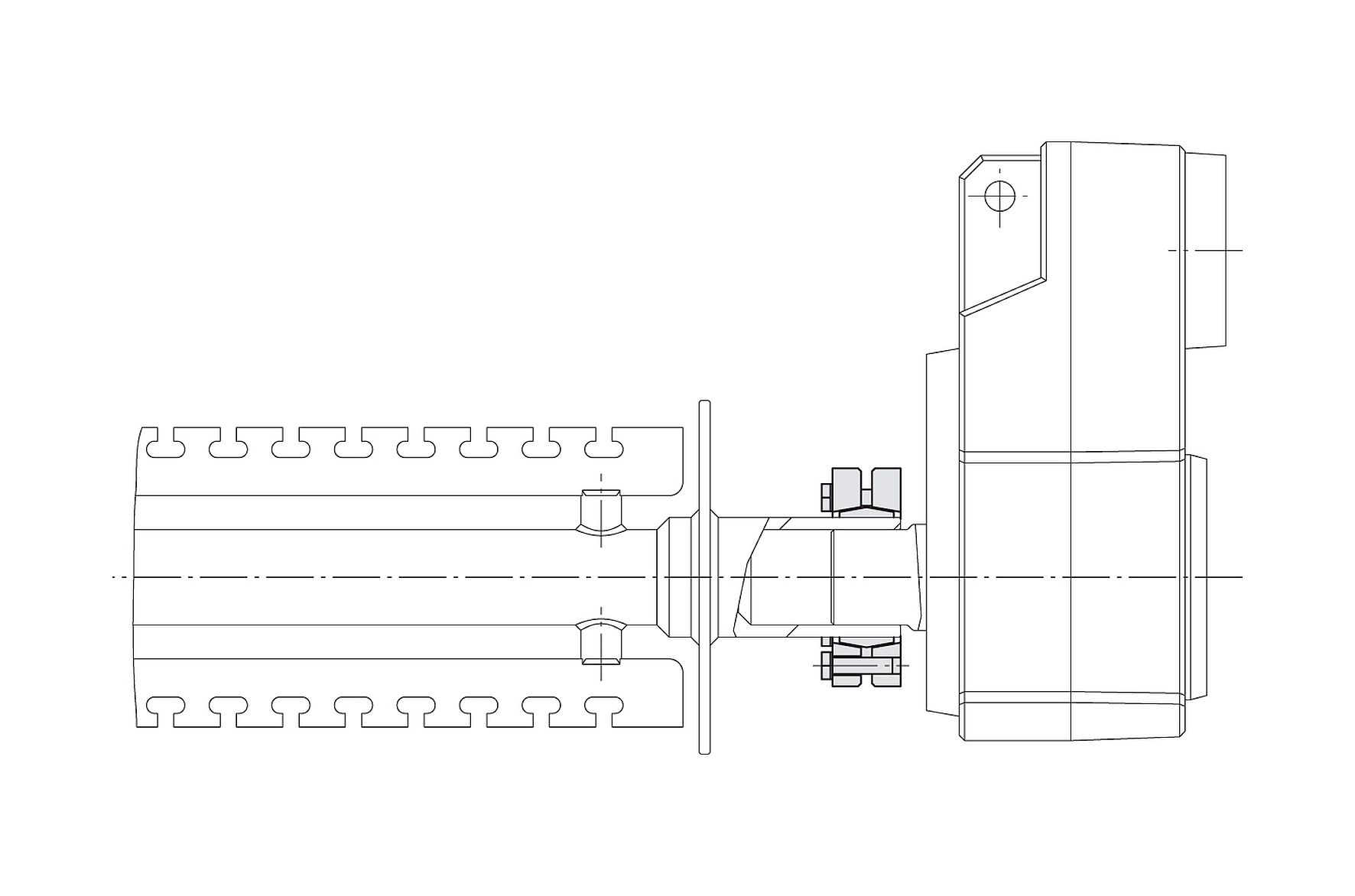

From a functional point of view, all RINGSPANN shrink discs and clamping elements are basically ready-to-install, largely standardised and frictionally connected shaft-hub-connections for the transmission of torques and axial forces. The corrosion-resistant stainless steel type RLK 603 K shrink discs are designed as a three-part assembly, which allows hollow shafts or hubs with outer diameters of 24 mm to 175 mm to be clamped from the outside onto rotating shafts without backlash. They are suitable for transmittable torques ranging from 170 Nm to 23,000 Nm and are adjusted and fixed with clamping screws.

One concrete food technology application example for such a stainless steel shrink disc is the backlash-free attachment of a stirring hook to the drive gear of a hygiene-sensitive screening unit for conditioning baking agents, which can be aligned in the direction of rotation. According to Marvin Raquet, "the design of the complete shrink disc in stainless steel - including all screws - in this case allows the realisation of a very maintenance-friendly and easy-to-clean drive solution". The stainless steel shrink discs type RLK 603 K are also a good choice for many process engineering applications because of their resistance to a number of chemicals. As an alternative to this, RINGSPANN offers three-part shrink disks in the RLK 603 S series, which can optionally be designed with chemically nickel-plated surfaces.

Nickel-plated surfaces

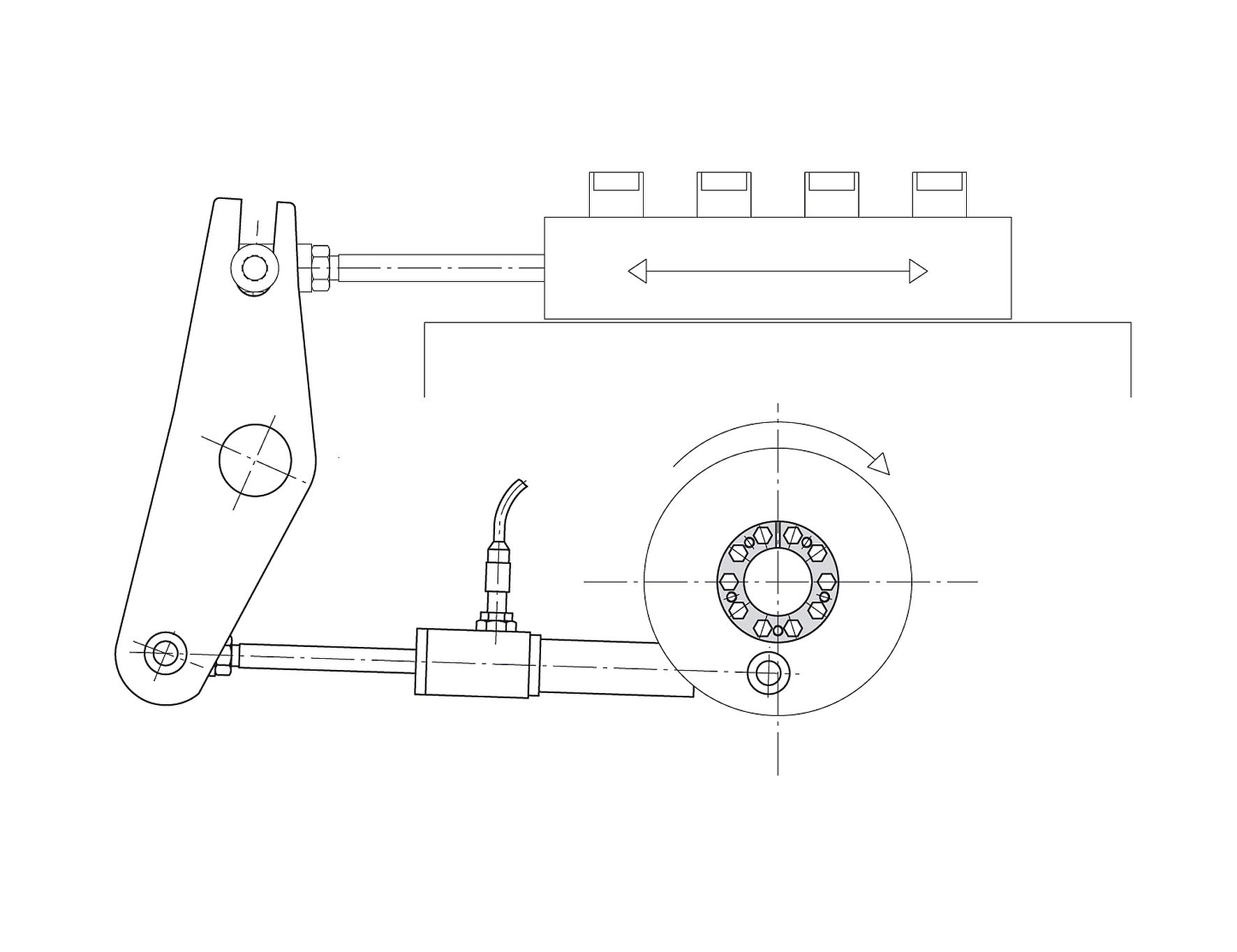

The cone clamping elements in the RLK 110 K series are nickel-plated as standard. With the help of these internal clamping connections, hubs can be fixed on rotating shafts with diameters from 19 mm to 60 mm. Depending on the variant, torques between 190 Nm and 2,800 Nm can be transmitted. Thanks to their radially flat height, these clamping elements from RINGSPANN are particularly suitable for use with hubs of smaller outer diameters. Their high corrosion resistance in accordance with DIN 50021 is achieved by a nickel coating, which in the standard version has a layer thickness of 35 µm. Product manager Marvin Raquet stresses in this context: "The nickel coating gives the RLK 110 K a high corrosion resistance per se, which is why this clamping element covers a wide range of applications in the food industry. However, since we can scale the thickness of the coating, the degree of corrosion protection can be individually adapted to the customer’s requirements. If, for example, a lower level of corrosion protection is sufficient and the cost framework is tight, we can also realise considerably thinner layer thicknesses".

A typical case for the use of a nickel-plated RLK 110 K is the backlash-free mounting of an eccentric wheel on the drive shaft of a food packaging machine. "In addition to nickel plating, we also offer our customers the option of designing these cone clamping elements in various stainless steels," adds Marvin Raquet.

Demand is growing

The corrosion-resistant shaft-hub-connections from RINGSPANN are currently experiencing growing demand. The company’s technicians see a triggering impulse for this in the increasing hygiene and quality demands that users in medical technology, the pharmaceutical industry and food processing place on machine and plant manufacturers. In addition, the increasing automation in these industries is increasing the demand for corrosion-resistant components for the realisation of drive technology assemblies. ar

Transmitting forces without loss

In order for a drive shaft to be able to transmit its rotating power without loss, it needs a safe and secure connection to the hub or shaft of the machine element to be moved. RINGSPANN offers a comprehensive portfolio of frictionally connected shaft-hub-connections for this purpose, which - depending on the design - can transmit both torque and axial forces. The current product catalogue provides a complete overview of the current portfolio of two and three-part shrink discs, cone clamping elements and star discs, star spring washers and torque motor clamping systems.